Choose towers that have been manufactured by PASMA members, because they prioritise your safety above all else. It’s a condition of membership that their towers meet the most up-do-date standards and are independently certified by a recognised and accredited certification organisation. Towers from PASMA manufacturing members are available for rental from PASMA hirer/dealer members.

Planning any work at height involves selecting the most suitable access equipment for the job. If you decide that’s a tower, you’ll also need to select the most appropriate configuration. After all, towers come in different shapes and sizes. The straight-up-and-down mobile access tower is a dependable and versatile piece of kit, but if you have obstacles to overcome or a wider work area to attend to, you’d be looking for a more complex configuration like a cantilever tower or linked towers. Learn all about these in our ultimate guide to towers.

Standards allow for different towers to have different capabilities. When you’re choosing a tower, pay close attention to a few key attributes to ensure it meets your needs. These details should be marked on the tower, the user instructions or on the supplier’s website:

Before you select a tower, think about the people, tools and equipment that will be on the structure at any one time. Find a tower that can carry that combined weight, by checking its safe working load (SWL). Some manufacturers will refer to this as the universally distributed load (UDL) or maximum distributed load (MDL).

How high do you need to reach? Check the maximum height of the tower (which is the maximum platform height that it can be built to) and ensure it will allow you easy access to your work area. The tallest possible height that an EN 1004-1 tower can go to is 8 metres outdoors and 12 metres indoors.

Towers are either single width (one platform) or double width (two platforms). They also come in different lengths, typically from about 1.5 to 3 metres between end frames. Which one you choose will depend on the space available on the ground and how much room you need at height.

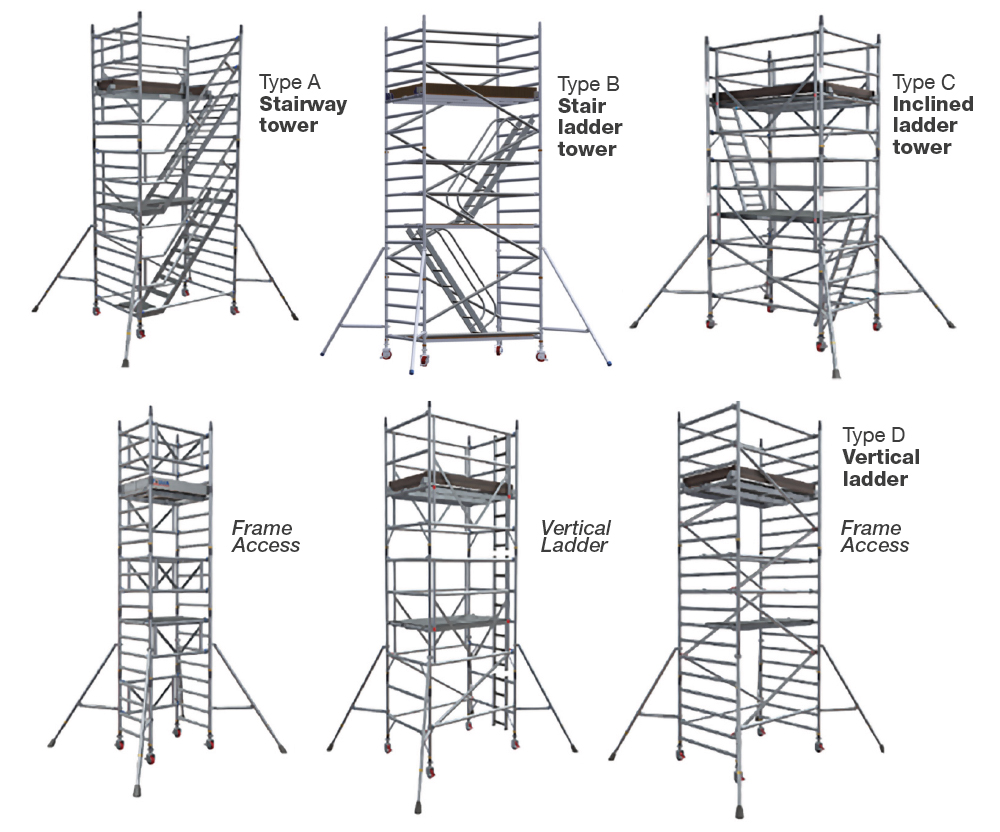

Towers can have different types of built in access, so you can go up and down safely. The options are:

A = stairway

B = stairladder

C = inclined ladder

D = vertical ladder

If you’ll be going up and down the tower frequently, use a stairway or stair ladder. If you have materials or larger tools or equipment to carry, you’ll need a stairway tower.

Check that your tower is certified to the relevant product standard, meaning it has been independently checked and certified by a recognised and accredited certification organisation such as Test & Research Centre, BSI or TUV. To be doubly sure, ask your supplier for a copy of the certificate. If they cannot provide this, you should seriously consider getting your tower from another source – a reputable supplier will be able to give it to you. Certification guarantees that it meets the minimum safety requirements.

Even a certified tower is only safe if it’s assembled, inspected, used and dismantled by competent workers. Anyone working with a mobile access tower should have a current PASMA Towers for Users qualification. This can be done at a PASMA training centre or on your own site, and can even be part-completed as e-learning.

Additional training is needed for anything other than a simple BS EN 1004-1 mobile access tower. There’s a range of BS 1139-6 tower configurations available, with a corresponding PASMA training course for each of them.

There’s an international network of PASMA-approved training centres who can provide these courses for you.

And finally, even although the person assembling the tower is trained, they must always have, and follow, the instruction manual provided by the manufacturer or hire company. Manuals are considered so important for safe use that they have their own special standard. That’s because they contain critical safety information, including:

PASMA hirer/dealer members stand ready to supply you with safe towers for your work at height needs.

Talk to them! They can offer advice and guidance to help you find the tower that suits you best.

Contact a PASMA memberMember Login Become A Member FAQs Contact

Head Office & Administration Centre

PO Box 26969

Glasgow, G3 9DR

T: +44 (0) 345 230 4041

E: info@pasma.co.uk

Prefabricated Access Suppliers’ & Manufacturers’ Association Ltd (PASMA)

is a Company Limited by Guarantee and registered in England, No. 1397880

Registered VAT No. (GB) 239 439 380.

Access Industry Management & Services Ltd (AIMS)

is a Private Limited Company, registered in England, No. 6923617

Registered VAT No. (GB) 239 439 380

is wholly owned by PASMA, and provides sales and services on behalf of PASMA to non-members.

Each have their registered address at: 10 Queen Street Place, London, EC4R 1BE